Canada Blower

http://nis-co.com/200/Index.html

http://nis-co.com/201/Index.html

http://nis-co.com/202/Index.html

http://nis-co.com/203/Index.html

http://nis-co.com/204/Index.html

http://nis-co.com/205/Index.html

http://nis-co.com/206/Index.html

http://nis-co.com/207/Index.html

http://nis-co.com/208/Index.html

http://nis-co.com/209/Index.html

http://nis-co.com/210/Index.html

http://nis-co.com/211/Index.html

http://nis-co.com/212/Index.html

http://nis-co.com/213/Index.html

http://nis-co.com/214/Index.html

http://nis-co.com/215/Index.html

http://nis-co.com/216/Index.html

http://nis-co.com/217/Index.html

http://nis-co.com/218/Index.html

http://nis-co.com/219/Index.html

http://nis-co.com/220/Index.html

http://nis-co.com/221/Index.html

http://nis-co.com/222/Index.html

http://nis-co.com/223/Index.html

http://nis-co.com/224/Index.html

http://nis-co.com/225/Index.html

http://nis-co.com/226/Index.html

http://nis-co.com/227/Index.html

http://nis-co.com/228/Index.html

http://nis-co.com/229/Index.html

http://nis-co.com/230/Index.html

http://nis-co.com/231/Index.html

http://nis-co.com/232/Index.html

http://nis-co.com/233/Index.html

http://nis-co.com/234/Index.html

http://nis-co.com/235/Index.html

http://nis-co.com/236/Index.html

http://nis-co.com/237/Index.html

http://nis-co.com/238/Index.html

http://nis-co.com/239/Index.html

http://nis-co.com/240/Index.html

http://nis-co.com/241/Index.html

http://nis-co.com/242/Index.html

http://nis-co.com/243/Index.html

http://nis-co.com/244/Index.html

http://nis-co.com/245/Index.html

http://nis-co.com/246/Index.html

http://nis-co.com/247/Index.html

http://nis-co.com/248/Index.html

http://nis-co.com/249/Index.html

http://nis-co.com/250/Index.html

http://nis-co.com/251/Index.html

http://nis-co.com/252/Index.html

http://nis-co.com/253/Index.html

http://nis-co.com/254/Index.html

http://nis-co.com/255/Index.html

http://nis-co.com/256/Index.html

http://nis-co.com/257/Index.html

http://nis-co.com/258/Index.html

http://nis-co.com/259/Index.html

http://nis-co.com/260/Index.html

http://nis-co.com/261/Index.html

http://nis-co.com/262/Index.html

http://nis-co.com/263/Index.html

http://nis-co.com/264/Index.html

http://nis-co.com/265/Index.html

http://nis-co.com/266/Index.html

http://nis-co.com/267/Index.html

http://nis-co.com/268/Index.html

Canada Blower Radial Fans

It is easy to get confused about fans. With so many different options,

you want to avoid purchasing the wrong product. As part of our product

line, we have several top-quality fans, blowers, and other industrial

and commercial products. Included in this are radial fans.

The difference between radial fans and conventional centrifugal fans is

the blade orientation. Because the design of these fans includes

backward curved blades, businesses typically use them for handling

combustion air. Due to their ruggedness and capability, these fans are

perfect for harsh environments. Because the blades curve away from the

rotating direction, these fans move a massive volume of air. However,

these fans also help cool air in large spaces. With a 90-degree change

of airflow, these fans are not just beneficial, but for many

applications, required.

The radial fans that we offer at Canada Blower are top-of-the-line.

Perfectly manufactured by some of the best companies in North America,

these fans are resilient, durable, and powerful enough to move a

significant amount of air. The fans that we provide are also easy to

clean and maintain, which is a huge bonus. Not only does this prevent

high costs for ongoing maintenance, but it also prevents downtime that

would negatively impact your business operations.

All of our radial-style fans at Canada Blower have a solid design that

guarantees high resiliency. For these fans as well as other products

that we offer, our prices are affordable. Ultimately, you get a

high-quality product at a competitive price. Although everyone benefits

from this combination, it is particularly useful for startup businesses

and those on a tight budget.

Radial Fans:

The following are the radial fans that we offer:

- Compact Radial Fans Maximum CFM 2,400, SP 14" WG,

temperature 600 F

- R20 Fans Maximum CFM 76,000, SP 22" WG, temperature 1,000

F

- R30 Fans Maximum 95,000, SP 32" WG, temperature 1,000 F

- R45 Fans Maximum 100,000, SP 46" WG, temperature 1,000 F

Although all radial fans are similar in how they perform, not all of

them have the same robust design as what we offer. All of our fans and

blowers are superior quality. That means that in addition to optimal

performance, our fans are durable, strong, and long-lasting. In

addition to moving air, you can use our fans to move gases.

Canada Blower "Baby"

Pressure Blowers offer:

- Straight radial blades of

heavy cast aluminum for self-cleaning feature, dynamically balanced for

efficient operation;

- AMCA tested and ASHRAE rated;

- Arc-welded 16 GA steel

housings and bases for rigidity and long life;

- Rotatable blower housing for

different discharge positions;

- Designed for industrial

applications such as: small exhaust systems where air is laden with

dust or grit and also for supplying high pressure air for pneumatic

conveying and cooling.

ANOTHER CANADA BLOWER PRODUCT

- TYPE HP PRESSURE BLOWERS:

... complete AMCA performance

& sound certification with capacities to 5,000 CFM @ 70" WG;

... efficiency ... advanced

wheel & aerodynamic housing combination for air-handling efficiency

and low sound levels superior to conventional radial wheel designs;

... stable blower

performance... the pressure curve remains stable from wide open to

closed off... fan surge conditions, or pulsation, is eliminated even

when turn-down approaches zero airflow;

... versatility... various

accessories, fan modifications, arrangements available: silencers,

flexible connectors, acoustical cladding, air-tight sealed,

spark-resistant & high-temperature construction, dampers.

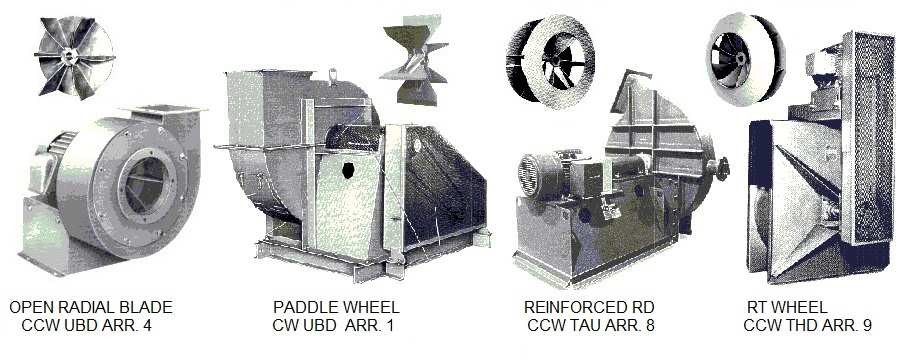

Industrial radial blower

RBO, RD, BP, LS, XO, DH, RTS,

Radial Tip Blowers:

industrial radial blade blowers are supplied in welded heavy gauge

steel construction to prevent flexing at high pressure. Available in

direct drive arrangements 4 / 4V / 4H / 7 / 8 and fan belt drive

arrangements

1/3/9/10. Arr. 10 blowers are known as ventilating sets (fan vent

sets).

Available in single width single inlet (SWSI), or double width double

inlet (DWDI) blower designs. Capacities: to 500,000 CFM. Static

pressure up to 100

inches water gauge depending on the class of construction. Typical

fan class of construction is Class 1, 2, 3, 4, 5.

Aluminum wheel, Steel wheel, or

FRP blower wheel:

industrial radial blowers and fans are supplied with aluminum wheel or

corten wheel to meet requirements of AMCA A, and AMCA B spark resistant

fan construction. Mild steel blower wheels are of all welded

construction. They

are used on pressure applications, material handling fan applications

(plastic scrap, paper trim, granular material, low density bulk

material) where wheel is reinforced with support gussets, or made of

abraision resistant construction, or furnished of high strenght steel.

Stainless steel ventilator wheel in 304 SS, 316 SS, 316 SS, 2205 SS are

supplied

for corrosive applications, or high tempearature applications. The

blower pressure curve remains stable from fully open to fully closed

position.

Inlet flanges, outlet flanges,

companion flanges: continuosly welded to match ANSI class 125/150,

DIN, ISO, or custom hole pattern.

Shaft seal and low leakage

blower construction:

shafting is straightened to close tolerance to minimize "run-out" and

ensure smooth operation. Teflon fan shaft seal, ceramic shaft seal and

lubricated shaft seals (Buna, Teflon, Viton) are standard. Red silicone

gasketing is provided for low leakage construction and for high

temperature construction. Heavy-duty spherical roller ventilator

bearings are

standard.

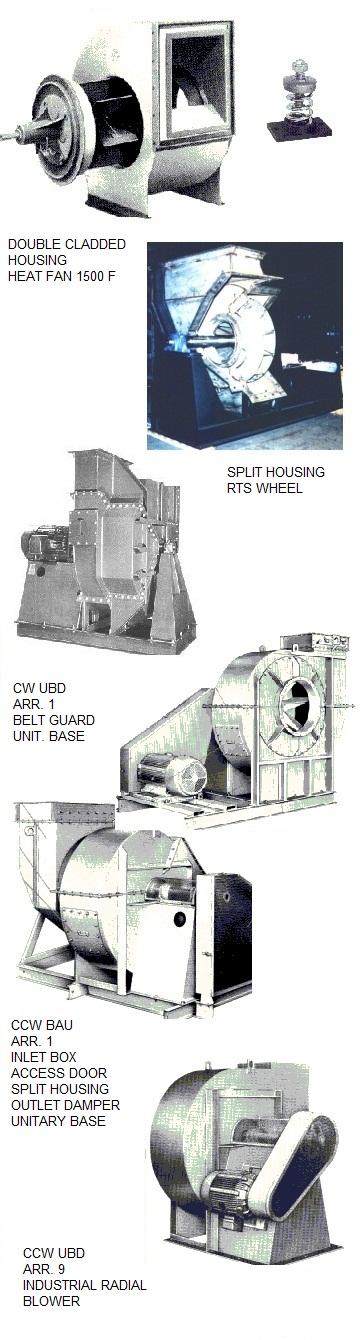

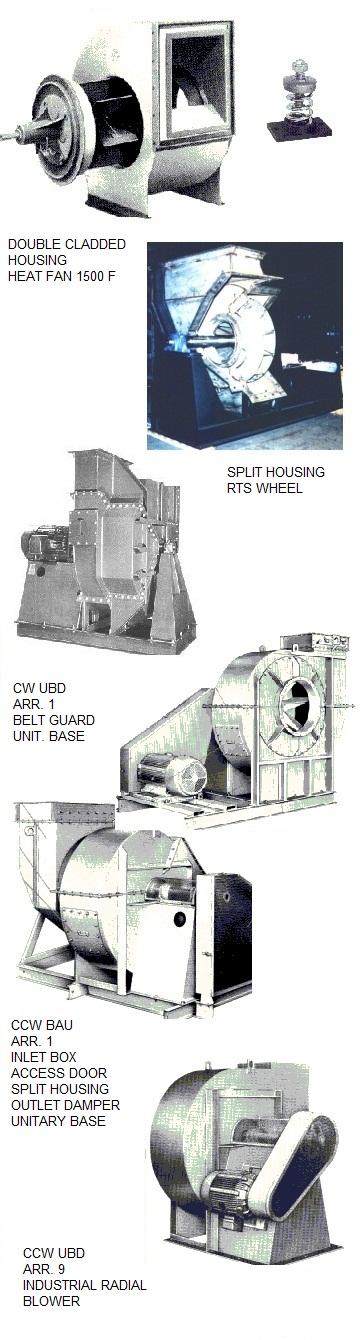

Heat fan construction up to

1500 F:

includes high temperature paint (up to 1000 F), special alloy

construction, shaft cooler, shaft-cooler guard, and steel wheel, or

alloy wheel, with steel, or alloy housing.

Cladding for sound attenuation

and silencers:

cladding consists of 2 inches mineral-wool insulation covered with a

welded steel jacket. As an inexpensive alternative is offered slide-on

acoustic cloth jackets. Inlet silencer/outlet silencer are supplied

with matching flanges for further attenuation of the noise level.

Inlet filter assemblies:

cell type, 1 inch, or 2 inch filters are available with filter cabinet

to be mounted at fan inlet. Bird guard, insect screen and weather hood

are optional accessories with inlet filter package.

Standard accessories:flash

/ raised access door, inspection port, drain and plug, unitary base,

shaft and bearing guard, belt guard, motor cover, spring vibration

isolation, rubber-in-share (RIS) vibration isolation, vibrating pads,

outlet damper, inlet vane damper, external inlet vane damper, evase,

electrical / pneumatic actuators.

APPLICATIONS:

Blow-off

Calciners

Combustion Air

Cooling

Cyclones

Dilution Air

Dryers

Dust Collection

Exhausting

Food and Dairy Processing

Forced Draft

Fume Exhaust

General Air Movement

Heating

High Temperature

Induced Draft

Light Dust Loading

Material Conveying

Material Handling

Oxidizers

Pollution Control

Pressurizing

Process Cooling

Process Heating

Saturated Air Fans

Scrubbers

Selective Catalytic Reduction

Spray Dryers

Tempering Air

Trim Handling

Industrial ventilators and fans,

process pressure

blowers, Canada Blower regenerative pressure blowers;

industrial; process and

commercial

heating; ventilating and air-conditioning equipment. Suppliers of cool air blowers, high

volume air ventilators, air blower motors, pneumatic blowers,

compressed air blowers, suction pressure blowers, air blower

compressores, high pressure axial fans, propeller fans, axial prop

fans, industrial fan motors, big industrial fans, large industrial

ventilators, industrial blower systems, explosion proof ventilation

fans, rooftop fans and ventilators, shop fans, building ventilation

fans.

Roof and wall exhaust and supply power ventilation fans for industrial

and commercial HVAC. Sales of axial propeller fans; inline blowers;

centrifugal fan ventilators; square in-line fans; FRP fan blowers; wall

and roof exhauster fans

Canada

Blower is a supplier of industrial process fans and blowers.

Canada Blower Compact Radial Blowers are ruggedly constructed fo a wide

variety of industrial air-handling processes, such as:

* dust collection

* grinding-booth exhaust

* scrubber exhaust

* food and drying ovens

* sawdust and wood-chip conveying

* paper-trim systems

Standard features of Canada Blower Compact Radial Blowers are:

- 8" through 14" radial wheel diameters provide capacities to 2400 CFM

and 14" SP

- airstream temperatures to 600 F with optional high-temp alloy blower

impeller

- heavy-gauge welded steel construction provide structural strength and

durability

- Compact Radial Blowers offer stabel, pulsation-free performance from

wide-open to closed-off

- paddle radial wheel is suitable for material-handling fan

applications.

|