About Us

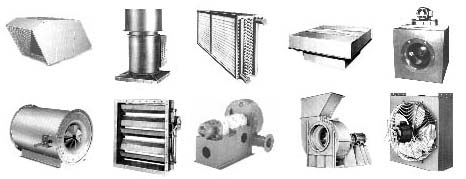

Canadian Blower is a leading supplier of industrial and commercial fans, ventilators, blowers and accessories for various air-moving applications.

Canadian Blower Co. offers a complete line of centrifugal fan equipment, from small Baby Vent Fan Sets capable of moving a few cubic feet per minute (CFM), to large, heavy-duty industrial mechanical draft fans with capacities to 1,000,000 CFM and with static pressures from 0" Water Gauge (WG) to 150" WG.

Howden blower products include standard centrifugal fan and customized blowers designed to meet our customers' requirements based on Canadian Blower manufacturing standard.

Over the years Canadian Blower / Canada Pump supplied centrifugal fans to a wide range of industries and commercial applications including: combustion air supply, material handling, process ventilation, ovens and dryers, iron and steel industry, mine and tunnel ventilation, petro-chemical, power generation, marine and off-shore structures, pulp and paper, HVAC, paint/spray booths, fertilizer and various emission control applications. For the commercial HVAC market, Canadian Blower offers general ventilation fans for institutional and retail buildings, schools, restaurants and hospitals. Special materials, construction, explosion-proof and spark-resistant fan design, variety of coatings and accessories are available to meet practically any fan application needs.

Canadian Blower fan repair, retrofit and service shop provides complete rebuilds, shaft repairs, blade liners, in-field balancing, vibration analyses, performance upgrade, increased fan capacity, all metallurgies, all type of fans repair, and emergency service on all sizes and designs.

Canadian Blower air moving products are best know for "industrial quality" assuring reliable performance, relentless dependability and longevity. A staff of specially trained engineers will design a dependable fan that exactly fits customers' dimensional and performance requirements.

Canadian Blower fans and lowers

are sold and serviced by air moving

experts that can evaluate your needs and provide best recommendations

for your application.

Canada Blower has the experience,

knowledge, and technology to produce what engineers and machine

designers agree to be the most durable and efficient industrial fans

and blowers:

Industrial Fans

Canada Blower offers the full range of the Industrial Fans &

Blowers. Options including Air Circulators, Tube Axial, Centrifugal,

Backward Curved & Inclined, and Ceiling Fans.

Fan / Blower Product List:

Inline Fans

Custom Fans

Centrifugal Ventilator Fans

Axial Ventilator Products

Plenums and Double Widths

Fiberglass Reinforced Plastic Fans

Process Heat or Plug Fans

Fan Components

Silencers / Flex Connectors

Applications:

Blow-off

Calciners

Combustion Air

Cooling

Cyclones

Dilution Air

Dryers

Dust Collection

Exhausting

Food and Dairy Processing

Forced Draft

Fume Exhaust

General Air Movement

Heating

High Temperature

Induced Draft

Light Dust Loading

Material Conveying

Material Handling

Oxidizers

Pollution Control

Pressurizing

Process Cooling

Process Heating

Saturated Air Fans

Scrubbers

Selective Catalytic Reduction

Spray Dryers

Tempering Air

Trim Handling

Sales of industrial fans & blowers, high pressure blowers, centrifugal fans, axial ventilators, roow and wall exhaust and supply fans, material handling blowers & radial fans, scroll cage fan ventilators, high temperature fans and blowers, New York Blower, Twin City Fan / Aerovent, Chicago Blower fans, Peerless Fans, Dayton Ventilators, Sheldons fans & blowers, Canarm Leader ventilators, IAP fans, Industrial Air.

Explosion proof backwardly inclined; airfoil; radial and radial-tip fans and blowers. Pressure blowers; plug fans; air kits; centrifugal and axial ventilators.

| http://buffalofan.com/index.html http://buffalofan.com/ahu.html http://buffalofan.com/aircurtain.html http://buffalofan.com/airhandler.html http://buffalofan.com/contact.html http://buffalofan.com/custserv.html http://buffalofan.com/fan.html http://buffalofan.com/fanblower.html http://buffalofan.com/faninquiry.html http://buffalofan.com/heatexchanger.html http://buffalofan.com/humidifier.html http://buffalofan.com/hvac.html http://buffalofan.com/liquidexchanger.html http://buffalofan.com/news.html http://buffalofan.com/silencer.html http://buffalofan.com/ventilator.html http://buffalofan.com/airblower.html http://buffalofan.com/airfan.html http://buffalofan.com/airventilator.html http://buffalofan.com/airtightblower.html http://buffalofan.com/blower.html http://buffalofan.com/blowerfan.html http://buffalofan.com/blowerimpeller.html http://buffalofan.com/blowerrepair.html http://buffalofan.com/blowerventilator.html http://buffalofan.com/blowerwheel.html http://buffalofan.com/blowerwheels.html http://buffalofan.com/blowers.html http://buffalofan.com/buffaloblower.html http://buffalofan.com/buffaloblowers.html http://buffalofan.com/buffalofan.html http://buffalofan.com/buffalofans.html http://buffalofan.com/centrifugalblower.html http://buffalofan.com/centrifugalfan.html http://buffalofan.com/conveyingblower.html http://buffalofan.com/dustcollectingblower.html http://buffalofan.com/dustcollectingfan.html http://buffalofan.com/dustcollectionfan.html http://buffalofan.com/dustcollectorblower.html http://buffalofan.com/dustcollectorfan.html http://buffalofan.com/exhaustblower.html http://buffalofan.com/exhaustblowers.html http://buffalofan.com/exhaustfan.html http://buffalofan.com/exhaustfans.html http://buffalofan.com/exhaustventilator.html http://buffalofan.com/fanblower.html http://buffalofan.com/fansblowers.html http://buffalofan.com/fanventilator.html http://buffalofan.com/fanventilators.html http://buffalofan.com/fans.html http://buffalofan.com/fumeexhaust.html http://buffalofan.com/fumeexhaustfan.html http://buffalofan.com/highpressureblower.html http://buffalofan.com/highpressurefan.html http://buffalofan.com/highpressureventilator.html http://buffalofan.com/hightemperatureblower.html http://buffalofan.com/hightemperaturefan.html http://buffalofan.com/industrialairblower.html http://buffalofan.com/industrialairfan.html http://buffalofan.com/industrialairproducts.html http://buffalofan.com/industrialblower.html http://buffalofan.com/industrialblowerfan.html http://buffalofan.com/industrialblowerventilator.html http://buffalofan.com/industrialblowers.html http://buffalofan.com/industrialfan.html http://buffalofan.com/industrialfanblower.html http://buffalofan.com/industrialfanventilator.html http://buffalofan.com/industrialfans.html http://buffalofan.com/industrialscrubber.html http://buffalofan.com/industrialscrubbers.html http://buffalofan.com/industrialventilator.html http://buffalofan.com/industrialventilatorblower.html http://buffalofan.com/industrialventilatorfan.html http://buffalofan.com/industrialventilators.html http://buffalofan.com/pneumaticblower.html http://buffalofan.com/pressureblower.html http://buffalofan.com/pressureblowerfan.html http://buffalofan.com/pressureblowers.html http://buffalofan.com/processblower.html http://buffalofan.com/processfan.html http://buffalofan.com/radialblower.html http://buffalofan.com/radialfan.html http://buffalofan.com/ventilatingblower.html http://buffalofan.com/ventilatingfan.html http://buffalofan.com/ventilationblower.html http://buffalofan.com/ventilationfan.html http://buffalofan.com/ventilatorblowers.html http://buffalofan.com/ventilatorfan.html |

| Centrifugal fans (centrifugal blowers) are

a common type of fan used in consumer and industrial products to move

air or other gases. A centrifugal fan consists of three main

components: a motor, a fan blade, and an enclosure. All of these blower components can be designed to accommodate an application. Some common fan design criteria are the size of the motor, the shape of the fan blade, the direction of rotation, and the materials of the fan construction. The rotating fan blade creates a low-pressure area at the center of the blade and a high-pressure area at the edges of the blade along with adding kinetic energy to the air. The low pressure area at the center of the fan creates a vacuum that draws air into the fan. The air flows from the center of the fan to the outside edges of the fan and then, ultimately, out of the enclosure around the impeller in the desired direction. The flow path makes a 90 degree turn in most cases which is accounted for in the design of the overall system. Both centrifugal fans and axial fans are commonly used in industrial environments, but they have very different performance characteristics. Axial fans are used in applications where a large flow rate is required with minimal drop in pressure. Axial fans pass air straight through the blades instead of creating a 90-degree turn in the direction of air flow. If there is not a large pressure drop in the application, the axial fan can be preferable due to form, fit, & function. In industrial contexts, axial fans are often used in equipment to exchange heat through environmental air such as Air-Cooled Condensers, Cooling Towers and Air Cooled Heat Exchangers. Examples include: Field erected cooling towers often utilized in industrial processes and in power generation facilities. Package cooling towers which are mainly used in HVAC applications. Air-cooled condensers which are a critical component in power plants and typically utilize large diameter fans. Air cooled heat exchangers (ACHE) which are used primarily in process industries (petrochemical, oil refining and gas compression). Forced ventilation systems. Centrifugal fans are typically placed in areas of little to no natural ventilation and are attached to a duct system, making them ideal for larger spaces. |