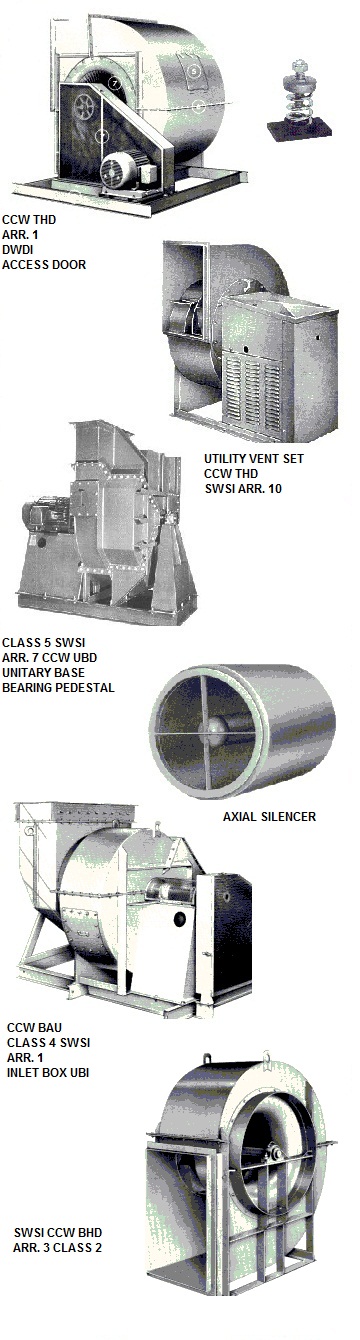

Industrial backward curved (BC) fan blower

SWSI,

DWDI, AcF, PLR, BI, BC, AF, ST, Backward Inclined Fans, Aerocline,

General

Purpose, GP, BL, Limit Load, LL, Buffalo Vent Set, BCV, BCA, BCM, BCS

fans:

industrial backward curved blowers are supplied in welded heavy gauge

steel construction to prevent flexing at high pressure. Available in

direct drive arrangements 4/4V/4H/7/8 and belt drive arrangements

1/3/9/10. Arr. 10 fan blowers are known as ventilating sets (vent

sets).

Available in single width single inlet (SWSI), or double width double

inlet (DWDI). Capacities: to 500,000 CFM. Static pressure up to 100

inches water gauge depending on the class of construction. Typical

class of construction is Class 1, 2, 3, 4, 5.

Backward-inclined fans offer lower

sound levels and energy costs in clean air applications; fan impeller

designed for high operating efficiency and high mechanical strength in

its specific blade angles.

Centrifugal plug fan is used in ovens and dryers to circulate clean air

and eliminate cold spots; also good in dust collector applications.

Aluminum wheel, Steel wheel, or Alloy wheel: industrial backward curved (bc) blowers and fans are supplied with aluminum fan wheel or corten wheel to meet requirements of AMCA A, and AMCA B spark resistant construction. Mild steelblower wheels are of all welded construction. If higher pressure is required wheel can be furnished of high strenght steel. Stainless steel ventilator wheel in 304 SS, 316 SS, 316 SS, 2205 SS are supplied for corrosive applications, or high temeparature applications. The fan pressure curve remains stable at the top are of the fan curve and to the right of the pick point.

Inlet flanges, outlet flanges, companion flanges: continuosly welded to match ANSI class 125/150, DIN, ISO, or custom hole pattern.

Shaft seal and low leakage construction: shafting is straightened to close tolerance to minimize "run-out" and ensure smooth operation. Teflon shaft seal, ceramic shaft seal and lubricated shaft seals (Buna, Teflon, Viton) are standard. Red silicone gasketing is provided for low leakage construction and for high temperature construction. Heavy-duty spherical roller bearings are standard.

Heat fan construction up to 800 F: includes high temperature paint, shaft cooler, shaft-cooler guard, and steel wheel, or alloy wheel.

Cladding for sound attenuation and silencers: cladding consists of 2 inches mineral-wool insulation covered with a welded steel jacket. As an inexpensive alternative is offered slide-on acoustic cloth jackets. Inlet silencer/outlet silencer are supplied with matching flanges for further attenuation of the noise level.

Inlet filter assemblies: cell type, 1 inch, or 2 inch filters are available with filter cabinet to be mounted at fan inlet. Bird guard, insect screen and weather hood are optional accessories with inlet filter package.

Standard accessories:flash

/ raised access door, inspection port, drain and plug, unitary base,

shaft and bearing guard, belt guard, motor cover, spring vibration

isolation, rubber-in-share (RIS) vibration isolation, vibrating pads,

outlet damper, inlet vane damper, external inlet vane damper, evase,

electrical / pneumatic actuators.

http://canadablower.com/about-us-2/

http://canadablower.com/products/

http://canadablower.com/products/industrial-fans-and-blowers/

http://canadablower.com/products/ventilators/

http://canadablower.com/products/air-handling-units/

http://canadablower.com/products/air-systems/

http://canadablower.com/oem/

http://canadablower.com/price-list/

http://canadablower.com/line-belt-driven-fan-price-chart/

http://canadablower.com/industrial-axial-inline-direct-driven-fans-price-chart/

http://canadablower.com/industrial-centrifugal-fans-price-chart/

http://canadablower.com/industrial-centrifugal-blowers-price-chart/

http://canadablower.com/wall-exhauster-price-chart/

http://canadablower.com/roof-exhauster-price-chart/

http://canadablower.com/wall-roof-supply-fans-price-chart/

http://canadablower.com/request-a-quote/

http://canadablower.com/policy/

http://canadablower.com/contact-us/

http://canadablower.com/blog/

http://canadablower.com/ebook/tab%202.html

http://canadablower.com/ebook/tab%201.html

http://canadablower.com/ebook/Tab%204.html

http://canadablower.com/ebook/Tab%206.html

http://canadablower.com/ebook/Tab%207.html

http://canadablower.com/ebook/Tab%208.html

http://canadablower.com/ebook/Tab%209.html

http://canadablower.com/ebook/Tab%2010.html

http://canadablower.com/ebook/Catalog%20C2000.html

Multistage Blowers deliver up to 150,000 SCFM of uncontaminated gas flow at up to 30 PSIG pressure, and from 20” to 0” Hg vacuum. Typical applications include air conveying, industrial & municipal water waste, water aeration, petroleum and chemical refineries, flotation, central vacuum systems, cell aeration, sulfur recovery, fluidized bed units, gas boosters for carbon dioxide, nitrogen, propane, natural gas, steam compressors for vapor recompression systems, electroplating, agitation of tanks, cement pneumatic conveying, landfill gas recovery, leaching process, soil remediation, paper transport, scrap collection, powder recovery, and all applications requiring medium pressure, or vacuum at relatively large volume of flow.

Multistage Blowers are available with cast iron, or fabricated steel casing enclosing cast aluminum, fabricated aluminum, or stainless steel rotors. ANSI 125/150 flange connections, as well as metric standard flange connections are standard. Shaft sealing is provided by labyrinth seal, mechanical seal, purgeable nitrogen, or other gas seal, gas tight seal, or by sealed bearing compartments.

Multistage Blower Packages are supplied on unitary base of standard or isolation type with RIS, or spring vibration isolators. Power transmission is implemented by V-Belt Drives complete with V-belts, adjustable or constant speed sheaves and pulleys, bushings, and motor slide bases; or by direct drive coupling. Motors are of High Efficiency design. OSHA Belt Guard and OSHA Coupling Guard are standard.

Sales of industrial fans & blowers, high pressure blowers, centrifugal fans, axial ventilators, roow and wall exhaust and supply fans, material handling blowers & radial fans, scroll cage fan ventilators, high temperature fans and blowers, New York Blower, Twin City Fan / Aerovent, Chicago Blower fans, Peerless Fans, Dayton Ventilators, Sheldons fans & blowers, Canarm Leader ventilators, IAP fans, Industrial Air. smoke ventilators, propeller fans, exhaust silencers, exhaust systems, kitchen and restaurant panel exhaust fans, welding fume exhausters.

Engineering Sales of Buffalo Blower / New York blower and fans, American Coolair, ILG Chicago, Illinois Blower, Industrial Gas Engineering Industrial air products, fan and blower including high temperature & high pressure blowers and fans, pressure blowers, heavy duty industrial process fans and blowers. Super high temperature fans, air tight and zero leakage blowers and centrifugal axial fans, explosion proof fans and ventilators

.