Industrial fan blower wheel

blades, replacement OEM fan lwheels, axial fan propellers,

industrial ventilators blades, Canada Blower pressure blowers impellers.

Canada Blower industrial aerfoil (AF) blowers and fans are supplied with aluminum wheel or corten wheel to meet requirements of AMCA A, and AMCA B spark resistant construction. Mild steel wheels are of all welded construction. If higher pressure is required wheel can be furnished of high strenght steel. Stainless steel wheel in 304 SS, 316 SS, 316 SS, 2205 SST are supplied for corrosive applications, or high temeparature applications. The pressure curve remains stable at the top are of the fan curve and to the right of the pick point.

Canada Blower is a leading supplier of industrial and commercial fans, ventilators, blowers and accessories for various air-moving applications.

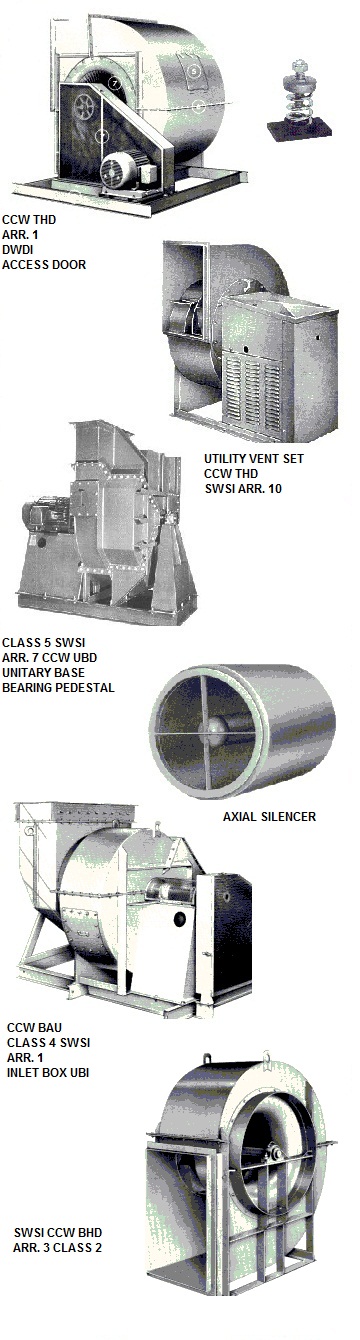

Buffalo Forge offers a complete line of centrifugal fan equipment, from small Canada Blower Baby Vent Sets capable of moving a few cubic feet per minute (CFM), to large, heavy-duty industrial mechanical draft fans with capacities to 1,000,000 CFM and with static pressures from 0" Water Gauge (WG) to 150" WG.

Canada Blower Howden blower products include standard centrifugal fan and customized blowers designed to meet our customers' requirements based on Canadian Blower manufacturing standard.

Over the years Canadian Blower / Canada Pump supplied centrifugal fans to a wide range of industries and applications including: combustion air supply, material handling, process ventilation, ovens and dryers, iron and steel industry, mine and tunnel ventilation, petro-chemical, power generation, marine and off-shore structures, pulp and paper, HVAC, paint/spray booths, fertilizer and various emission control applications. For the commercial HVAC market, Canada Blower offers general ventilation fans for institutional and retail buildings, schools, restaurants and hospitals. Special materials, construction, explosion-proof and spark-resistant design, variety of coatings and accessories are available to meet practically any application needs.

Canada Blower fan repair, retrofit and service shop provides complete rebuilds, shaft repairs, blade liners, in-field balancing, vibration analyses, performance upgrade, increased fan capacity, all metallurgies, all type of fans repair, and emergency service on all sizes and designs./p>

Canadian Blower air moving products are best know for "industrial quality" assuring reliable performance, relentless dependability and longevity. A staff of specially trained engineers will design a dependable fan that exactly fits customers' dimensional and performance requirements.

Canada Blower fans and lowers are sold and serviced by air moving experts that can evaluate your needs and provide best recommendations for your application.

SWSI and DWDI industrial aerofoil fan blowers are supplied in welded heavy gauge steel construction to prevent flexing at high pressure. Canada Blower centrifugal fans are available in direct drive arrangements 4 / 4V/ 4H / 7 / 8 and belt drive arrangements 1 / 3 / 9. CB airfoil fans are available in single width single inlet (SWSI), or double width double inlet (DWDI). Capacities: to 500,000 CFM. Static pressure up to 50 inches water gauge depending on the class of construction. Typical class of construction is Class 1, 2, 3, 4 and 5.

Supply air or clean exhaust application is ideal for Canada Blower SQA airfoil fans. For dirty air or dusty air, the Buffalo Blower SQB version with backward inclined blades is recommended. The SQA is also suited for high temperature gases handling as well as for air conveying applications.

Inlet flanges, outlet flanges, companion flanges are continuosly welded to match ANSI class 125/150, DIN, ISO, or custom hole pattern. Shaft seal and low leakage construction can be furnished with shafting straightened to close tolerance to minimize "run-out" and ensure smooth operation. Teflon shaft seal, ceramic shaft seal and lubricated shaft seals (Buna, Teflon, Viton) are standard. Red silicone gasketing is provided for low leakage construction and for high temperature construction. Heavy-duty spherical roller bearings are standard.

Canada Blower heat fan construction goes up to 1000 F and includes high temperature paint, shaft cooler, shaft-cooler guard, and steel wheel, or alloy wheel. Cladding for sound attenuation and silencers consists of 2 inches mineral-wool insulation covered with a welded steel jacket. As an inexpensive alternative is offered slide-on acoustic cloth jackets. Inlet silencer/outlet silencer are supplied with matching flanges for further attenuation of the noise level.

Inlet filter assemblies available are available too: cell type, 1 inch, or 2 inch filters are available with filter cabinet to be mounted at fan inlet. Bird guard, insect screen and weather hood are optional accessories with inlet filter package.

Standard Canada Blower fan / blower accessories include: flash / raised access door, inspection port, drain and plug, unitary base, shaft and bearing guard, belt guard, motor cover, spring vibration isolation, rubber-in-share (RIS) vibration isolation, vibrating pads, outlet damper, inlet vane damper, external inlet vane damper, evase, electrical / pneumatic actuators.

Industrial suppliers for pneumatic conveying blowers, corrugated materal handling fans, radial wheel blowers, high pressure radial ventilators, paper trim handling fans, industrial combustion OEM blowers, high pressure blowers in series, dryer fans, paint booth ventilators, roof exhaust ventilators, huge fans, high RPM blowers, high speed centrifugal blowers, Twin City utility sets, ventilating sets, high CFM ventilators, large wheel ventilators, narrow pressure blowers, all stainless steel ventilators,metal conveying fans.

Direct drive fans and blowers, gas tight fans and blowers, insulation blowers and fans, Northern Blower Sales, Twin City fans.

Canada Blower industrial aerfoil (AF) blowers and fans are supplied with aluminum wheel or corten wheel to meet requirements of AMCA A, and AMCA B spark resistant construction. Mild steel wheels are of all welded construction. If higher pressure is required wheel can be furnished of high strenght steel. Stainless steel wheel in 304 SS, 316 SS, 316 SS, 2205 SST are supplied for corrosive applications, or high temeparature applications. The pressure curve remains stable at the top are of the fan curve and to the right of the pick point.

Canada Blower is a leading supplier of industrial and commercial fans, ventilators, blowers and accessories for various air-moving applications.

Buffalo Forge offers a complete line of centrifugal fan equipment, from small Canada Blower Baby Vent Sets capable of moving a few cubic feet per minute (CFM), to large, heavy-duty industrial mechanical draft fans with capacities to 1,000,000 CFM and with static pressures from 0" Water Gauge (WG) to 150" WG.

Canada Blower Howden blower products include standard centrifugal fan and customized blowers designed to meet our customers' requirements based on Canadian Blower manufacturing standard.

Over the years Canadian Blower / Canada Pump supplied centrifugal fans to a wide range of industries and applications including: combustion air supply, material handling, process ventilation, ovens and dryers, iron and steel industry, mine and tunnel ventilation, petro-chemical, power generation, marine and off-shore structures, pulp and paper, HVAC, paint/spray booths, fertilizer and various emission control applications. For the commercial HVAC market, Canada Blower offers general ventilation fans for institutional and retail buildings, schools, restaurants and hospitals. Special materials, construction, explosion-proof and spark-resistant design, variety of coatings and accessories are available to meet practically any application needs.

Canada Blower fan repair, retrofit and service shop provides complete rebuilds, shaft repairs, blade liners, in-field balancing, vibration analyses, performance upgrade, increased fan capacity, all metallurgies, all type of fans repair, and emergency service on all sizes and designs./p>

Canadian Blower air moving products are best know for "industrial quality" assuring reliable performance, relentless dependability and longevity. A staff of specially trained engineers will design a dependable fan that exactly fits customers' dimensional and performance requirements.

Canada Blower fans and lowers are sold and serviced by air moving experts that can evaluate your needs and provide best recommendations for your application.

SWSI and DWDI industrial aerofoil fan blowers are supplied in welded heavy gauge steel construction to prevent flexing at high pressure. Canada Blower centrifugal fans are available in direct drive arrangements 4 / 4V/ 4H / 7 / 8 and belt drive arrangements 1 / 3 / 9. CB airfoil fans are available in single width single inlet (SWSI), or double width double inlet (DWDI). Capacities: to 500,000 CFM. Static pressure up to 50 inches water gauge depending on the class of construction. Typical class of construction is Class 1, 2, 3, 4 and 5.

Supply air or clean exhaust application is ideal for Canada Blower SQA airfoil fans. For dirty air or dusty air, the Buffalo Blower SQB version with backward inclined blades is recommended. The SQA is also suited for high temperature gases handling as well as for air conveying applications.

Inlet flanges, outlet flanges, companion flanges are continuosly welded to match ANSI class 125/150, DIN, ISO, or custom hole pattern. Shaft seal and low leakage construction can be furnished with shafting straightened to close tolerance to minimize "run-out" and ensure smooth operation. Teflon shaft seal, ceramic shaft seal and lubricated shaft seals (Buna, Teflon, Viton) are standard. Red silicone gasketing is provided for low leakage construction and for high temperature construction. Heavy-duty spherical roller bearings are standard.

Canada Blower heat fan construction goes up to 1000 F and includes high temperature paint, shaft cooler, shaft-cooler guard, and steel wheel, or alloy wheel. Cladding for sound attenuation and silencers consists of 2 inches mineral-wool insulation covered with a welded steel jacket. As an inexpensive alternative is offered slide-on acoustic cloth jackets. Inlet silencer/outlet silencer are supplied with matching flanges for further attenuation of the noise level.

Inlet filter assemblies available are available too: cell type, 1 inch, or 2 inch filters are available with filter cabinet to be mounted at fan inlet. Bird guard, insect screen and weather hood are optional accessories with inlet filter package.

Standard Canada Blower fan / blower accessories include: flash / raised access door, inspection port, drain and plug, unitary base, shaft and bearing guard, belt guard, motor cover, spring vibration isolation, rubber-in-share (RIS) vibration isolation, vibrating pads, outlet damper, inlet vane damper, external inlet vane damper, evase, electrical / pneumatic actuators.

Industrial suppliers for pneumatic conveying blowers, corrugated materal handling fans, radial wheel blowers, high pressure radial ventilators, paper trim handling fans, industrial combustion OEM blowers, high pressure blowers in series, dryer fans, paint booth ventilators, roof exhaust ventilators, huge fans, high RPM blowers, high speed centrifugal blowers, Twin City utility sets, ventilating sets, high CFM ventilators, large wheel ventilators, narrow pressure blowers, all stainless steel ventilators,metal conveying fans.

Direct drive fans and blowers, gas tight fans and blowers, insulation blowers and fans, Northern Blower Sales, Twin City fans.